- attached aileron trim springs to pushrod, using inboard skin as a guide - it was somewhat difficult to get perfect "neutral" position of pushrod

- deburred edges of inboard bottom skin; deburred, dimpled and riveted flap gap and aileron gap fairings; tried to attach pins on micro-molex (got 3 good ones, 2 crappy ones that have to be redone - ordered more micro-molex pins and redo)

- deburred edges and holes of outboard and inboard bottom skins; final-drilled #19 holes; filed down and primed forward overlap of inboard/outboard skins

- attached springs to servo trim arm; attached 3 of 5 wires (with micro-molex pins) to micro-molex connector body

- riveted inboard bottom skin to wing assembly and riveted all nutplates onto inboard bottom skin; also had visitor (Terrell Y.; also constructing an RV-14A) and showed him how I rivet bottom skins

- riveted 90% of the outboard bottom skin - what a pain in the ass

- finished riveting everything on the bottom skins (including access nutplates), except for 29 rivets near skin junction (need wife to help with these); drilled, deburred and dimpled access plates

- deburred holes (4 skins) and edges (2 of 4 skins) of aileron skins for both wings

- finished deburring last 2 aileron skins; dimpled everything for the left aileron and also for parts of the right aileron (prematurely for trailing edge of skins, but this should still work - might be better; UPDATE - the ailerons are very straight, so I might choose this tactic for the right aileron); clecoed together left aileron assembly; reamed trailing edge @ ~8 deg angle (performed outside trailing edge since I already dimpled the trailing edge portion of the skins); disassembled left aileron

- riveted nose skin to nose ribs, top skin and bottom skin to spar, counterweight to skin, and side ribs to each other

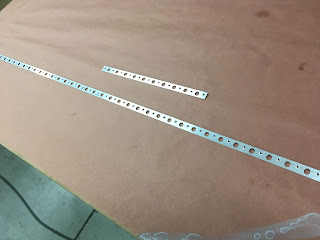

Flap and aileron gap fairings clecoed to right wing assembly: