It was all flaps, all week long. I nearly finished the left flap (waiting for a squeezer set from Cleaveland Tool for the trailing edge) and am midway through the right flap. The hardest part of the flaps is riveting the bottom skin to the spar, but after I figured out how to position the tungsten bucking bar, it wasn't too bad. I checked and confirmed that the twist between the two brackets was <0.1deg using an iPhone digital leveling app. If Paul Dye uses an iPhone to level parts, I figured it would be a safe way to do it.

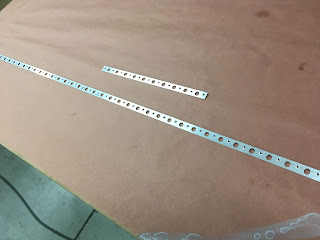

Countersunk the inboard and outboard trailing edges for the left flap:

Sunday, July 28, 2019

Sunday, July 21, 2019

Section 20 - Bottom Wing Skins (finished left outboard skin); Section 23 - Aileron Actuation (torque tube install; pushrod install)

If I haven't yet mentioned how much I dislike riveting bottom wing skins, let me mention it here: it sucks, bigly. But, they are now done, with some help from my wife on areas that I simply couldn't stretch to rivet (about 80 rivets in two bays). I departed from Van's instructions, and just riveted everything that I could reach at the point I could best reach the rivets. This generally meant going from inboard to outboard (thanks Ken B. for this suggestion!) and aft to forward where possible. For parts that I could not rivet on my own, my wife manned the rivet gun and I streeeeetched to reach rivets in unsightly places. Once the skins were done, I then attached the torque tube (didn't need any extra washers for spacing) and final-installed the torque tube-to-bellcrank pushrod. I noticed that the pushrod is right in the area where my nice pitot/AOA tubing needs to go; when I final-install the Garmin GAP-26, I'll have to bend the tubing around the pushrod a bit. The left wing went back in the wing stand, the right main spar came out of the crate, and the crate was ejected from the workshop. Progress!

Oh, and I helped Ken B. move his RV-14A wings to a hangar, as well as mount an engine! There are certain tasks like these that require a village ... or at least a couple extra hands.

Early on in riveting the left outboard lower skin - those 8 rivets around the flap bracket are a real chore:

Oh, and I helped Ken B. move his RV-14A wings to a hangar, as well as mount an engine! There are certain tasks like these that require a village ... or at least a couple extra hands.

Early on in riveting the left outboard lower skin - those 8 rivets around the flap bracket are a real chore:

Monday, July 15, 2019

Section 20 - Bottom Wing Skins (riveted inboard lower skin); Section 21 - Flaps (prepped skins; drilled wedge, nose ribs, hinge brackets); Section 23 - Aileron Actuation (finished torque tube and pushrods)

Good progress this week, especially considering I spent much of it slowly riveting the inboard lower skin to the wing (and did that entire skin without assistance from a bucking partner). I bought a new 1.5lb tungsten bar that fits in tight spaces far better than my larger tungsten bar, which aided the process considerably. Of course, there was a learning curve - for example, if the bucking bar doesn't feel right, don't just pull the trigger (i.e., I made a couple slight dings). Likewise, I started this process with the gun air pressure way too high, and soon dialed it back down after a few rivets. Overall, the lower skins are a real pain in the ass - you work for every rivet by stretching, figuring out how to bend the skin some (but not too much) in order to reach ... not a fun process, but a decent learning experience. The rest of the week included finishing the left torque tube, the left bellcrank-to-aileron pushrod, and making good progress on the left flap. Details follow:

Riveted the threaded rod end to the internally primed steel tube by sloooowly squeezing the -11 (!) rivets with the Cleaveland Tool Main Squeeze manual squeezer. These long rivets wanted to lean over, so I had to adjust the angle several times:

Riveted the threaded rod end to the internally primed steel tube by sloooowly squeezing the -11 (!) rivets with the Cleaveland Tool Main Squeeze manual squeezer. These long rivets wanted to lean over, so I had to adjust the angle several times:

Sunday, July 7, 2019

Section 20 - Bottom Wing Skins (prepped lower skins; wired/plumbed pitot/AOA); Section 21 - Flaps (both skeletons/assemblies); Section 23 - Aileron Actuation (2 pushrods, left bellcrank, torque tube subs)

I got a ton accomplished this past ~week:

1) riveted nutplates to Gretz mount; started and finished tubing and wiring Garmin GAP-26 heated Pitot/AOA (had to enlarge 8 holes to fit SB500-6 snap bushings)

2) Fabricated left torque tube to bellcrank pushrod; installed left aileron bellcrank upside down)

3) reinstalled left aileron bellcrank correctly; fabricated torque tube subassemblies (CS-00009 and WD-1014)

4) BOTH sides - fabricated flap/aileron cradle; drilled hinge brackets; rod-end rib subassembly (drilled, deburred); hinge pair rib subassembly (drilled, deburred); cut tabs on ribs

5) BOTH sides - deburred all ribs (edges/holes); deburred spars; attached main and nose ribs and hinge assemblies to spars; fabricated trailing edge wedges (VA-140); assembled flap skeletons

6) used new die grinder and cutoff wheel to cut aileron to bellcrank pushrod and torque tube collar; drilled pushrod, match-drilled threaded rod ends, deburred pushrod and rod ends, primed inside of pushrod.

Importantly, Ken B., a fellow RV-14A builder and experienced RV mentor, was kind enough to drive an hour each way to visit my project and check my work ... and (as always) he let me ask him a bunch of questions. Thanks again, Ken!!! It's nice to know that I can "build on" rather than have to redo anything major :)

Finished fabricating the Gretz pitot mount (riveted nutplates, and checked install on wing):

1) riveted nutplates to Gretz mount; started and finished tubing and wiring Garmin GAP-26 heated Pitot/AOA (had to enlarge 8 holes to fit SB500-6 snap bushings)

2) Fabricated left torque tube to bellcrank pushrod; installed left aileron bellcrank upside down)

3) reinstalled left aileron bellcrank correctly; fabricated torque tube subassemblies (CS-00009 and WD-1014)

4) BOTH sides - fabricated flap/aileron cradle; drilled hinge brackets; rod-end rib subassembly (drilled, deburred); hinge pair rib subassembly (drilled, deburred); cut tabs on ribs

5) BOTH sides - deburred all ribs (edges/holes); deburred spars; attached main and nose ribs and hinge assemblies to spars; fabricated trailing edge wedges (VA-140); assembled flap skeletons

6) used new die grinder and cutoff wheel to cut aileron to bellcrank pushrod and torque tube collar; drilled pushrod, match-drilled threaded rod ends, deburred pushrod and rod ends, primed inside of pushrod.

Importantly, Ken B., a fellow RV-14A builder and experienced RV mentor, was kind enough to drive an hour each way to visit my project and check my work ... and (as always) he let me ask him a bunch of questions. Thanks again, Ken!!! It's nice to know that I can "build on" rather than have to redo anything major :)

Finished fabricating the Gretz pitot mount (riveted nutplates, and checked install on wing):

Subscribe to:

Posts (Atom)