During the last ~2 weeks I bounced around a bit, depending on what needed to be accomplished (and to afford time for curing/drying/cogitating/omphaloskepsis). Nothing earth-shattering, except to mention that ALL the remote boxes have either been installed or holes have been drilled for their eventual installation. Having so many remote boxes made it quite a challenge to locate everything behind the panel - but they will all fit. Specifically, I accomplished the following:

- drilled a few holes to attach Garmin boxes; lots of planning; modified left avionics shelf for GAD29 and IBBS attachment

- installed GEA24, GAD27, GAD29, IBBS and left avionics panel

- installed CO detector, identified and routed many loose wires through firewall passthroughs; took off upper and lower cowl, and locked remaining camlocs

- uninstalled GAD29, IBBS, and 4 connections to GEA24; drilled 4 holes for main power bus connector and attached connector; reattached aforementioned items

- sanded inlet ramps, epoxy/flox/micro of aft edges (will smooth out so baffle rubber will close neatly around the prior gap)

- sanded epoxy/micro on upper cowl; bondo-filled all holes holes and sanded (3x repeated); coated all sanded areas with light layer of epoxy

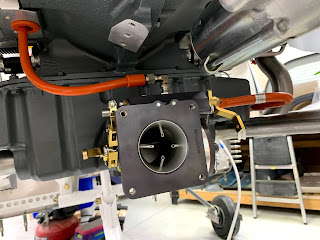

- installed fuel pressure sensor and manifold pressure sensor; completed a few odds-and-ends

- started installing the exhaust pipes - installed the hanger for tailpipe, and placed and loosely attached the aft and forward exhaust pipes (used nickel anti-seize paste at slip joints)

- finished installing exhaust system; torqued flange nuts 16 lb-ft; drilled out 2 LP4-3 rivets from right heat vent and installed cover w/red RTV

- prepared and installed heat muff assemblies; prepared scat hoses for vents (cut, trimmed, RTV’d the length of each hose); organized hardware

- Installed vent t-splitter that directs hot air to left/right cabin floor vents; installed a few scat hoses, while leaving others off for access (for fuel line penetrating cabin - prosealed the fitting to the firewall, but will need to final-torque nut and fuel line later)

View behind the panel - damn, that's a lot of wires! Avionics shelf was fabricated (next pics) to hold the IBBS battery (black rectangular box in the center) and GAD29 (underneath shelf; not shown):